Wheelset Maintenance

Wheelset Maintenance

Wheelset Measuring Stand

The Wheelset Measuring Stand is designed for the measurement of dismantled wheelsets. The aim of the measurement is the final dimensional inspection of each finished wheelset after re-profiling or a pre-measurement of individual wheelsets before the maintenance. The coordinate measuring device has a special design and is equipped with an optical laser measuring system. User software visualizes the measurement results and clearly classifies them according to appropriate criteria.

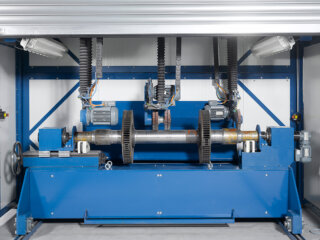

Axle Measuring Stand

The Axle Measuring Stand was developed for quality control of the geometry of railway axles. It is used by the axle manufacturer or in wheelset workshops to check the exact dimensional condition of the axles and also to determine the diameter for pairing with wheels, bearings, gears boxes, etc.

Wheelset Inspection Stand

The Wheelset Inspection Stand is used in wheelset workshops at the beginning of the maintenance process. As a result, relevant information is obtained which is important for the subsequent maintenance stage.

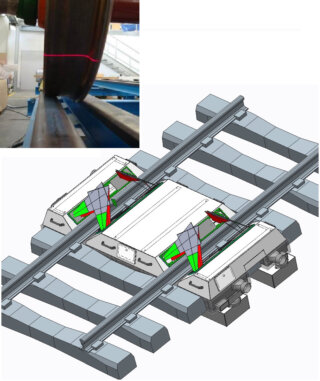

Rollover System for Profile Measurement

This stationary measuring device installed in a track is used to measure various geometric parameters on wheel discs while the train is slowly moving over the facility. In this way, the condition of the wheels is continuously monitored and preventive measures for necessary repairs can be derived. This condition-based maintenance can optimize the service life of the wheel.

Wheelset Cleaning

The Axle Cleaning Stand

The axle cleaning systems from bip technology operate fully automatically, they subsequently pass the wheel sets on for reworking and are equipped with a high-quality dust removal system to safeguard against explosive hazards. The systems are also used for roughening for renewed paint coating. With this cleaning process the surface of pre-programmed axles can be roughened on wheelsets.

High-Pressure-Water-Blast Plant

The application-flexible High-Pressure Water Blast technology enables material-friendly non-abrasive cleaning or depainting of wheelsets, bogies and vehicle components with the support of a robot. The robot-guided water jets are moved along the contours of the wheelset with a rotating water blasts and a pressure of up to 2,500 bar, thus reaching the complete surface of the wheelset without changing its structure. Further post-processing is no longer necessary.

A successful replacement of physically heavy and time-consuming work is thus proven. This innovative process has now been used for the first time in the world in an automated version and provides a time- and resource-saving solution for heavy wheelset maintenance, increases process reliability and facilitates the transition to the requirements of "Industry 4.0".

Wheelset Transportation Technology

Wheelset Turntable

The Wheelset Turntable is used to change the movement direction of the wheelset within the workshop. The design of the wheelset turntable ranges from manual, semi-automatic to fully automatic movement. It can be networked with other machine systems and equipment.

Wheelset Cross Conveyor

The Cross Conveyor can automatically distribute wheelsets to different lanes. It is controlled by motor, by line control sensors or by the operator through the select key.

Wheelset Lifting Table

Wheelset Lifting Table allows the wheelset to be lifted to an ergonomic height and to perform manual tasks such as visual checks and measurements or mounting or dismounting of bearings, etc.

Wheelset Lifting Turntable

The Lifting Turntable is used to lift the wheelset to an ergonomic working height for mounting bearings or other work and then to change the direction of rotation with regard to further transportation.

Storage For The Wheelsets

Multiple storage and floor storage for wheelsets are one of the most frequently used elements for stopping and intermediate storage of wheelsets, for forwarding and holding as well as for storing wheelsets in front of automated machines and equipment.

Wheelset Roll Stand

The Wheelset Toll Stand is used to set a wheelset in a rolling motion in order to carry out certain processes such as testing, measuring, cleaning and painting.

Wheelset Workshop Equipment

Workshop Equipment

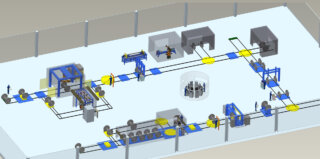

bip technology GmbH offers a wide range of products for wheelset workshops. The automated machines aim to achieve greater efficiency and cost optimisation for various processes in the workshop. bip offers you high-quality workshop equipment such as automated ultrasonic testing systems, wheelset depainting and cleaning systems, wheelset measuring systems and transport technology for wheelsets – everything from one hand.

With more than 40 engineers, technicians and project managers, bip technology GmbH combines the know-how and experience in the railway and workshop sector to successfully implement your project and optimise your processes with automated solutions. If you are still at the beginning of your project and are looking for a partner for workshop planning, bip will be happy to help you find an experienced workshop planner.