Ultrasonic Testing Systems

Hollow Axle Testing Equipment

The Mobile Hollow Axle Inspection System for longitudinally bored wheelset axles has been specially developed for railroad operators using vehicles with the same or very similar hollow axles, where mobility and the level of investment pay an important role. The system can be applied either directly on the vehicles or on separate wheelsets.

Solid Axle Testing Equipment

The goal of the Stationary Ultrasonic Inspection System for wheelset solid axles is to perform automated ultrasonic inspections on solid axles in the dismantled state in order to find several types of defects. It is used in wheelset workshops and can be integrated into a fully automated production line.

The Mobile Solid Axle Ultrasonic Inspection System was specially developed for railroad operators or ultrasonic service providers. It can be used either directly on the vehicles or on dismantled wheelsets to inspect the solid axles.

Wheelset Testing Station

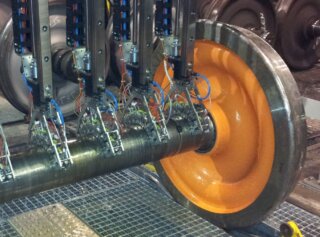

The Stationary Ultrasonic Wheel Inspection System is used for automated inspection of wheel running surface and wheel disc. It is used in wheelset workshops, but can also be integrated into a fully automated production line.

The Ultrasonic Wheel Inspection System with immersion technology is used for automatic ultrasonic defect inspection at the wheel running surface on railroad wheelsets. It is mainly used in wheelset production and often also in large heavy transport workshops.

Underfloor Testing Devices

The mobile underfloor ultrasonic inspection device was specially developed for rail operators to inspect the wheel running surface for mechanical damage such as cracks or volume defects directly on the train in the maintenance depot.

The stationary ultrasonic wheel inspection device was specially developed for railroad operators to inspect wheels, running surfaces or wheel discs for mechanical damage such as cracks or volume defects fully automatically directly on the train in the maintenance depot.

The ultrasonic underfloor inspection system, which is installed in the track and can be moved, makes it possible to automtically inspect all wheelsets stationary on the train and to display and store the results in accordance with the inspection requirements.

The purpose of the inspection system is the automated non-destructive inspection of wheel rims on wheelsets installed on the train for volume defects, for defects in the tread and profile and at the transition to the web with ultrasound and, as an option, on the tread with eddy current.

The system can be used to inspect various wheelset types in the rail depot.